We always use AC demo lenses for optical frames, but for sunglasses, there are MORE options. Below is a guide to your selection.

Sunglasses lens material:

- CR-39: High optical quality and tinting flexibility

- Nylon: Great clarity and freedom of design

- PC (Polycarbonate): Impact resistance and excellent hard coating durability

- Polarized technology: improved vision incorporated in the above-listed materials for glare reduction and safe

- TAC Polarized: Cheapest polarized option

Sun lens colors:

| – Solid (MONI) | – Gradient | – Double gradient(two tone) |

|  |  |

Additional Coatings if necessary:

Anti-reflective (AR) coating

Anti-Scratch-resistant coating (protect lenses get scratched, normally use for REVO color)

FILTER CATEGORY:

According to European standard NF EN ISO 12312-1 2013 (sunglasses for general use), there are 5 categories rated from 0 to 4, based on the transmission percentage, which means how much light the lens lets through.

Normally category 3 is well suited to all light conditions for daily use, for the others, it depends on how you use them.

Our Sun lenses brands cooperation partner: Zeiss& Ever Young

|  |

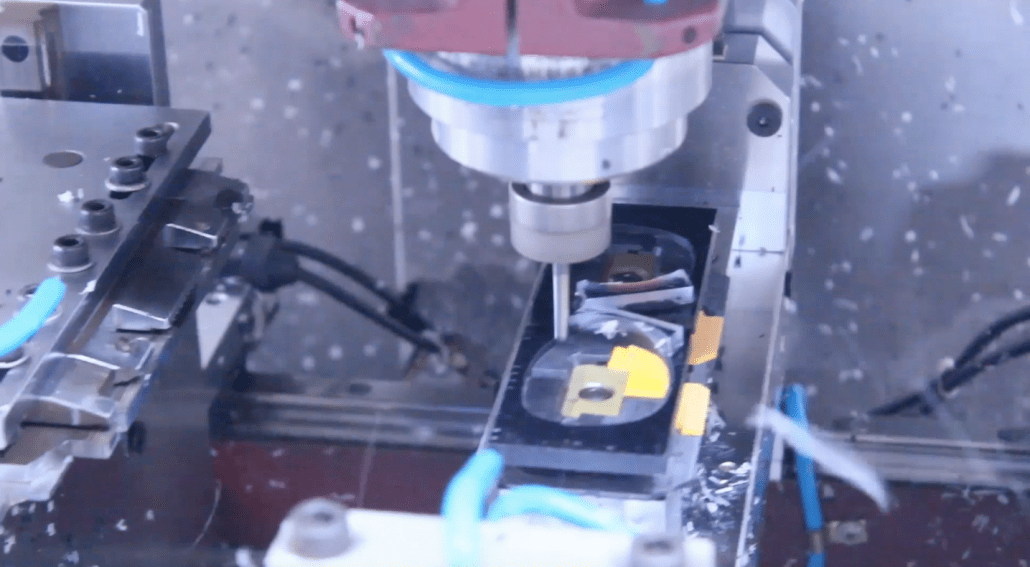

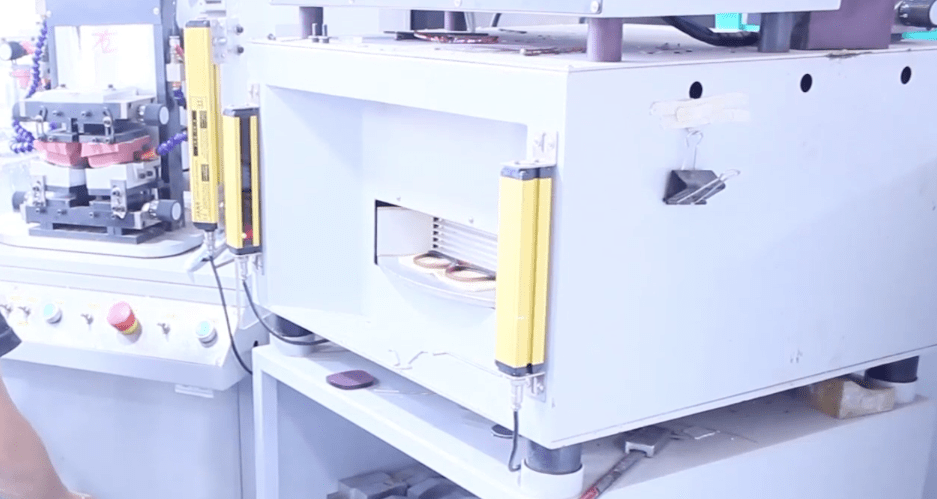

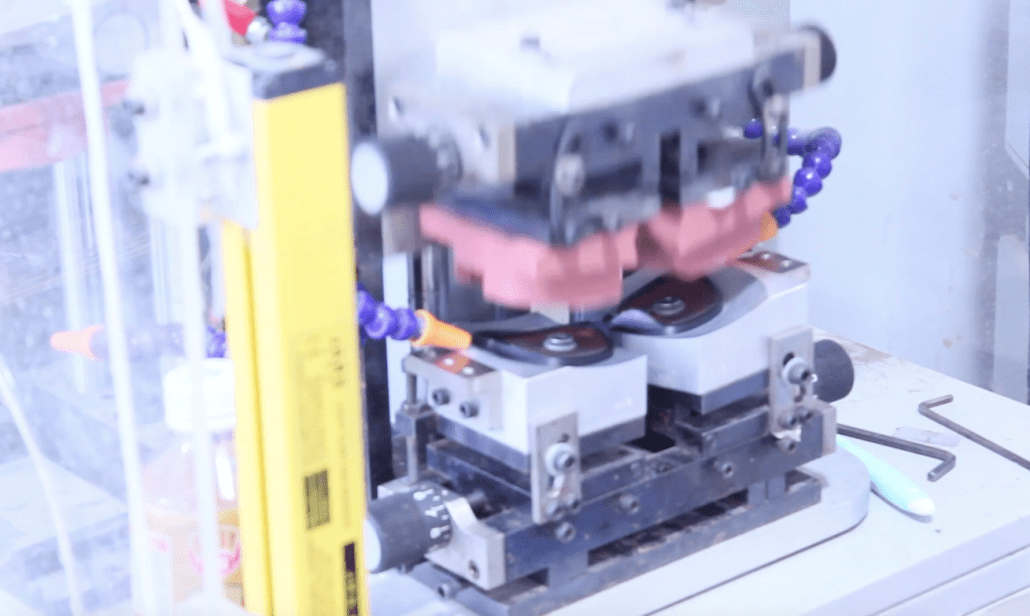

After getting the lenses from the lens supplier, we will also strictly quality check before we cut and assemble the glasses.

Article Copyright – www.leaoeyeglassfactory.com